Admiralty Brass

- Home

- >

- Condenser Tubes

- >

- Admiralty Brass

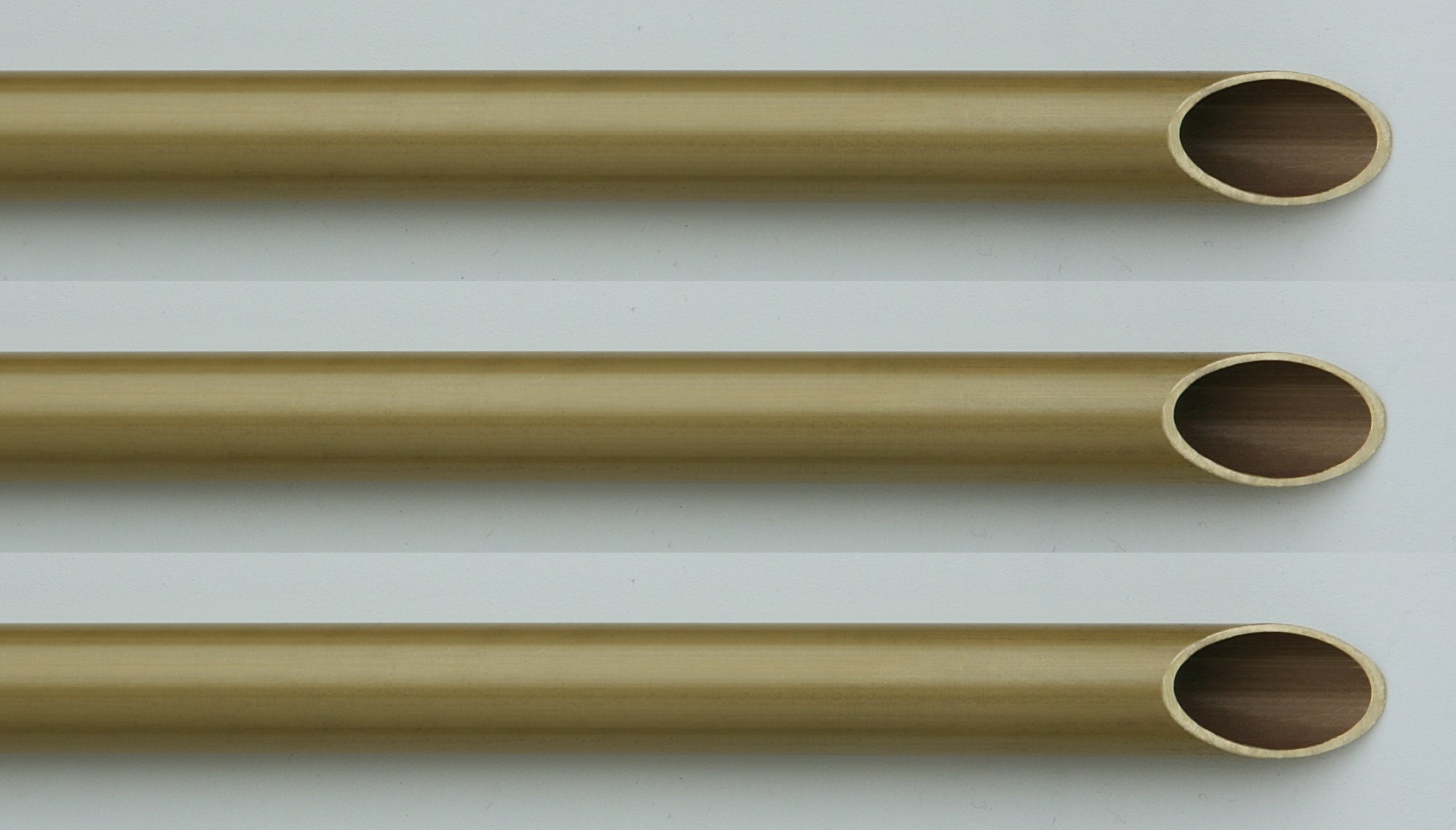

Admiralty Brass

Admiralty brass is a type of brass alloy known for its excellent corrosion resistance, especially in seawater, making it particularly suitable for marine applications. Here are the key details about Admiralty brass:

Composition:

Admiralty brass typically consists of:

- Copper (Cu): Approximately 70-73%

- Zinc (Zn): Approximately 27-30%

- Trace amounts of other elements such as iron (Fe), lead (Pb), tin (Sn), and arsenic (As).

Grades

ASTM B 111 C 44300 / ASME SB 111 C 44300:

- ASTM B 111: Standard specification for copper and copper-alloy seamless condenser tubes and ferrule stock.

- ASME SB 111: Identical to ASTM B 111, but used in ASME Boiler and Pressure Vessel Code applications.

BS 2871 Part 3 CZ-111:

- BS 2871: British Standard specification for copper and copper alloys. Part 3 covers wrought and cast high conductivity copper alloys for electrical purposes.

- CZ-111: Specifically refers to Admiralty brass within the British Standard system.

EN 12451 CuZn28:

- EN 12451: European Standard for copper and copper alloys. CuZn28 specifically denotes Admiralty brass (Cu 71-73%, Zn 27-29%).

SniAs - CW 706B:

- SniAs: Often refers to the Indonesian National Standard for Admiralty brass.

- CW 706B: Classification according to the British Standard system for copper alloys.

51 102 / CuZn29Sn1:

- 51 102: Identification number for Admiralty brass alloys.

- CuZn29Sn1: Another designation for Admiralty brass, specifying its composition (Cu 70-72%, Zn 28-30%, Sn 0.9-1.2%).

JIS H C 4430:

- JIS: Japanese Industrial Standard.

- H C 4430: Japanese standard designation for Admiralty brass.

Properties:

Corrosion Resistance: Admiralty brass exhibits exceptional resistance to corrosion, particularly in marine environments where seawater exposure is common. This is due to the alloy’s high copper content.

Strength: It has good strength, which is advantageous for structural applications.

Machinability: Admiralty brass is relatively easy to machine and work with, which enhances its utility in manufacturing processes.

Weldability: It is weldable using standard techniques, which allows for ease of fabrication.

Heat Conductivity: Like other brass alloys, Admiralty brass has good thermal conductivity, making it useful in heat exchanger applications.

Applications:

Marine Equipment: Admiralty brass is widely used in the marine industry for components like condenser tubes, heat exchanger tubes, fittings, and fasteners.

Heat Exchangers: Its corrosion resistance and thermal conductivity make it ideal for heat exchanger tubes in industrial applications.

Plumbing: Used in plumbing fittings and fixtures due to its corrosion resistance and durability.

Automotive: In some cases, Admiralty brass is used in automotive radiators and heater cores.

Other Products

Admiralty Brass

Admiralty brass is a type of brass alloy known for its excellent corrosion resistance, especially in seawater, making it particularly suitable for marine applications. Here are the key details about Admiralty brass:

Composition:

Admiralty brass typically consists of:

- Copper (Cu): Approximately 70-73%

- Zinc (Zn): Approximately 27-30%

- Trace amounts of other elements such as iron (Fe), lead (Pb), tin (Sn), and arsenic (As).

Properties:

Corrosion Resistance: Admiralty brass exhibits exceptional resistance to corrosion, particularly in marine environments where seawater exposure is common. This is due to the alloy’s high copper content.

Strength: It has good strength, which is advantageous for structural applications.

Machinability: Admiralty brass is relatively easy to machine and work with, which enhances its utility in manufacturing processes.

Weldability: It is weldable using standard techniques, which allows for ease of fabrication.

Heat Conductivity: Like other brass alloys, Admiralty brass has good thermal conductivity, making it useful in heat exchanger applications.

Applications:

Marine Equipment: Admiralty brass is widely used in the marine industry for components like condenser tubes, heat exchanger tubes, fittings, and fasteners.

Heat Exchangers: Its corrosion resistance and thermal conductivity make it ideal for heat exchanger tubes in industrial applications.

Plumbing: Used in plumbing fittings and fixtures due to its corrosion resistance and durability.

Automotive: In some cases, Admiralty brass is used in automotive radiators and heater cores.

ASTM B 111 C 44300 / ASME SB 111 C 44300:

- ASTM B 111: Standard specification for copper and copper-alloy seamless condenser tubes and ferrule stock.

- ASME SB 111: Identical to ASTM B 111, but used in ASME Boiler and Pressure Vessel Code applications.

BS 2871 Part 3 CZ-111:

- BS 2871: British Standard specification for copper and copper alloys. Part 3 covers wrought and cast high conductivity copper alloys for electrical purposes.

- CZ-111: Specifically refers to Admiralty brass within the British Standard system.

EN 12451 CuZn28:

- EN 12451: European Standard for copper and copper alloys. CuZn28 specifically denotes Admiralty brass (Cu 71-73%, Zn 27-29%).

SniAs - CW 706B:

- SniAs: Often refers to the Indonesian National Standard for Admiralty brass.

- CW 706B: Classification according to the British Standard system for copper alloys.

51 102 / CuZn29Sn1:

- 51 102: Identification number for Admiralty brass alloys.

- CuZn29Sn1: Another designation for Admiralty brass, specifying its composition (Cu 70-72%, Zn 28-30%, Sn 0.9-1.2%).

JIS H C 4430:

- JIS: Japanese Industrial Standard.

- H C 4430: Japanese standard designation for Admiralty brass.