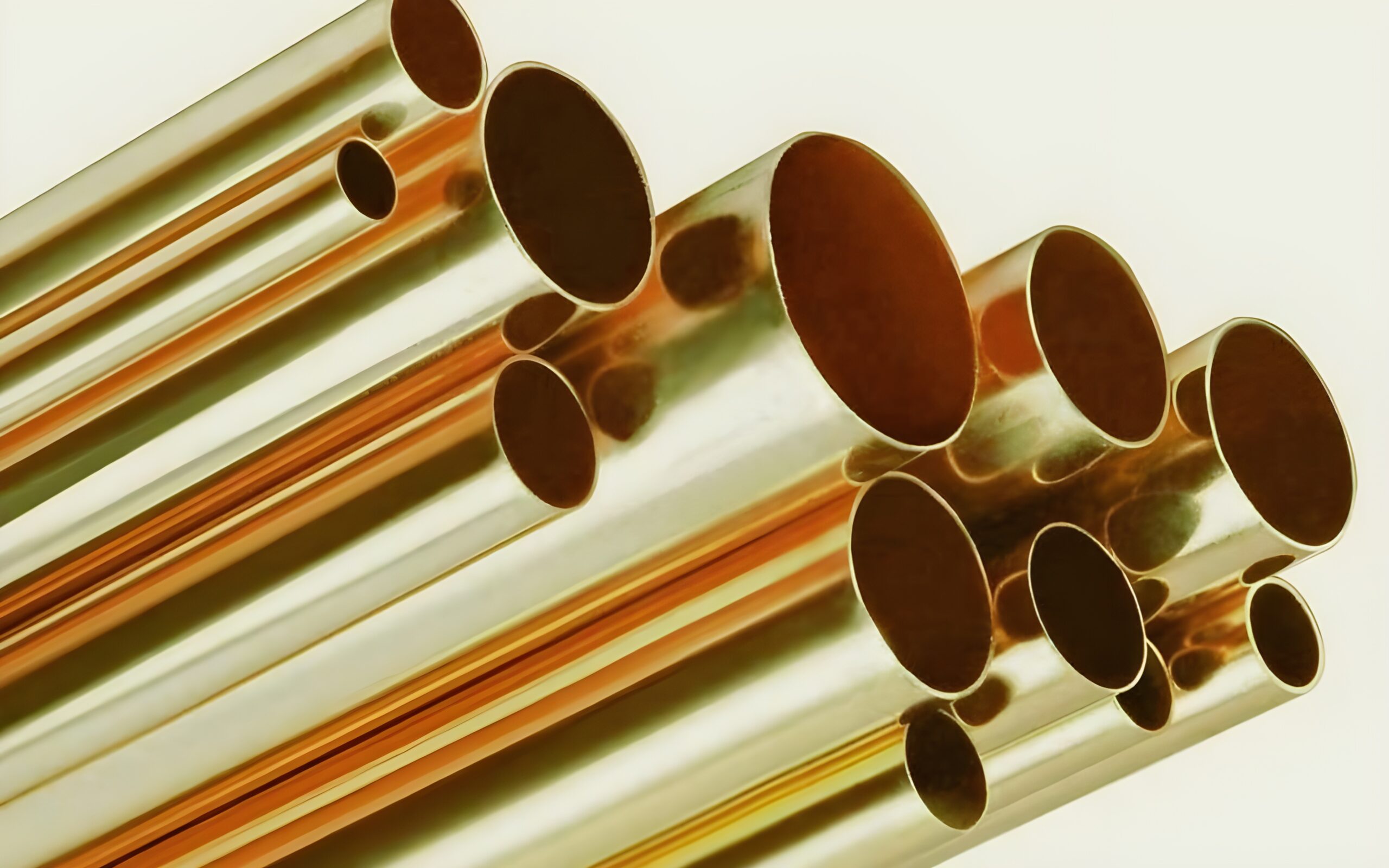

70/30 Brass

- Home

- >

- Lead Free Brass

- >

- 70/30 Brass

70/30 Brass

Lead-Free Brass 70/30, also known as Cartridge Brass or 70/30 Brass, is a copper-zinc alloy known for its excellent corrosion resistance, good strength, and ductility. It is commonly used in applications requiring good mechanical properties and resistance to dezincification.

Composition:

- Copper (Cu): 70%

- Zinc (Zn): 30%

- Lead (Pb): <0.09% (Lead-Free)

Grades

ASTM B 135 C 26000:

- ASTM B135: Standard Specification for Seamless Brass Tube.

- C26000: Designation for 70/30 Brass in this standard.

BS 2871 Part 3 CZ - 126:

- British Standard for copper and copper alloys – Tubes.

- CZ 126: Designation for 70/30 Brass in this standard.

EN 12449 CuZn30As CW 505L:

- European standard for copper and copper alloys – Seamless, round tubes for general purposes.

- CW 505L: European designation for 70/30 Brass.

NFA 51 102 CuZn30:

- French standard for copper and copper alloys.

- CuZn30: Designation for 70/30 Brass.

JIS H 3300 C 2600:

- Japanese Industrial Standard for copper and copper alloy seamless tubes.

- C 2600: Japanese designation for 70/30 Brass.

AS 1572 26130:

- Australian standard for copper and copper alloy seamless tubes.

- 26130: Designation for 70/30 Brass.

Properties:

- Corrosion Resistance:

- Excellent resistance to corrosion in various environments, including freshwater and mildly acidic conditions.

- Good resistance to dezincification and stress corrosion cracking.

- Mechanical Properties:

- Tensile Strength: Typically around 300-450 MPa.

- Yield Strength: Approximately 100-200 MPa.

- Elongation: Generally around 30-45%, indicating good ductility.

- Hardness: Moderate hardness, with a typical Brinell hardness number (HB) of around 70-110.

- Thermal and Electrical Conductivity:

- Good thermal conductivity, making it suitable for heat exchanger applications.

- Moderate electrical conductivity, less than pure copper but sufficient for many industrial uses.

Applications:

Plumbing and Heating: Used extensively in plumbing systems, fittings, and valves due to its corrosion resistance and ease of fabrication.

Heat Exchangers: Ideal for heat exchanger tubes and other thermal applications due to its good thermal conductivity.

Industrial Applications: Employed in various industrial equipment, including marine hardware and fasteners.

Electrical Applications: Used in electrical connectors and components where moderate conductivity is sufficient.