Nickel Silver

- Home

- >

- Leaded Brasses

- >

- Nickel Silver

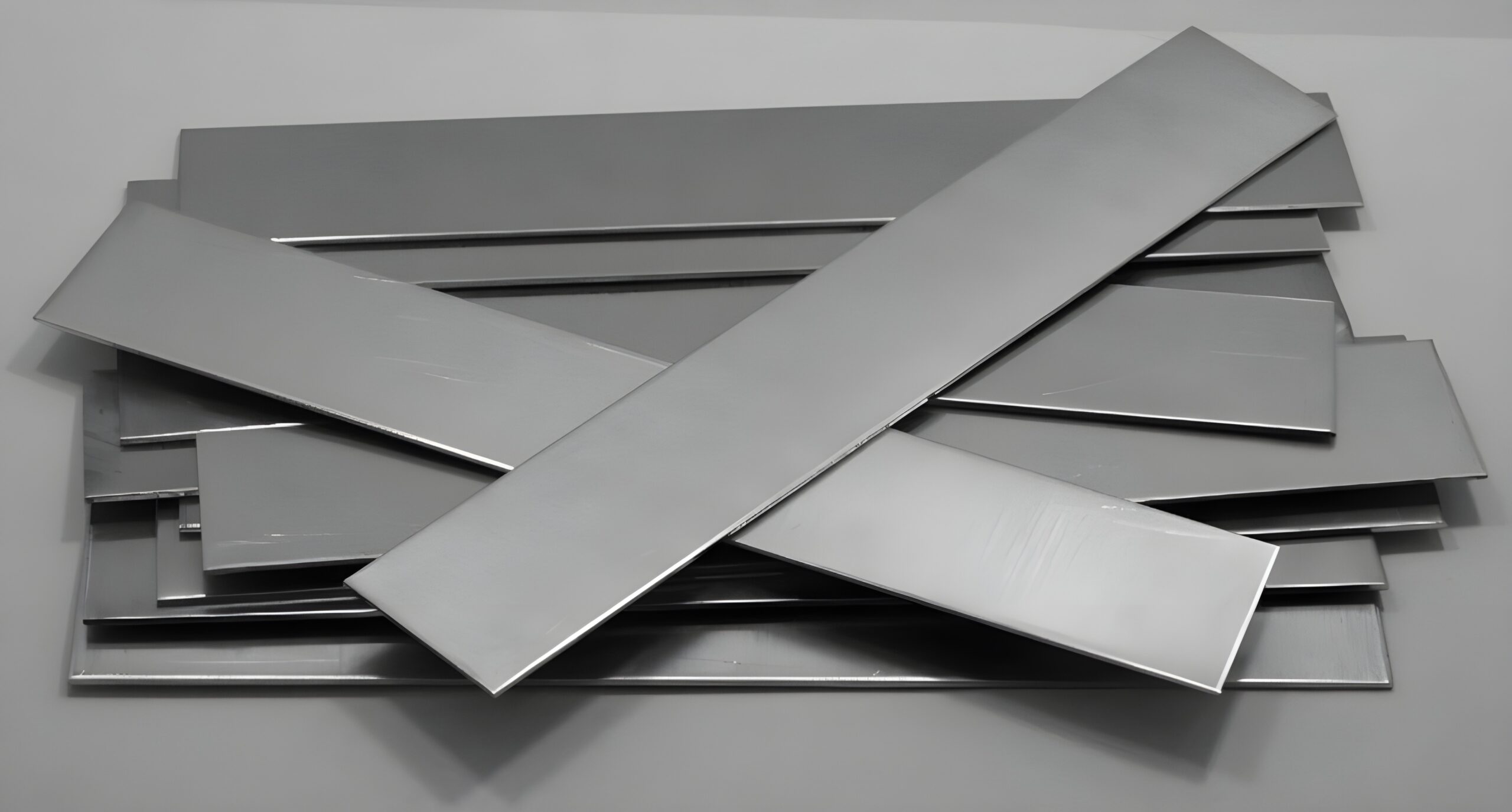

Nickel Silver

Nickel Silver, also known as German Silver, is a copper alloy with nickel and zinc, and often contains lead for improved machinability. Despite its name, it contains no silver but has a silvery appearance due to its nickel content. This alloy is known for its corrosion resistance, mechanical strength, and attractive appearance.

Composition:

- Copper (Cu): Approximately 60-65%

- Nickel (Ni): Approximately 10-20%

- Zinc (Zn): Approximately 20-25%

- Lead (Pb): Approximately 0.5-2%

- Other elements: May include small amounts of iron (Fe) and manganese (Mn) to enhance specific properties.

Grades

IS 10757 Nickel Silver:

Indian Standard specifying the composition and mechanical properties for nickel silver alloys.

BS 2874 Ns 101:

British Standard specifying the requirements for nickel silver alloys.

ASTM 79830 / Nm3 / Nm6 / C79830:

ASTM standards specifying the composition and mechanical properties for various grades of nickel silver alloys.

Properties:

- Corrosion Resistance:

- Excellent resistance to corrosion in a variety of environments, including marine and industrial.

- Particularly resistant to tarnish, making it suitable for decorative applications.

- Mechanical Properties:

- Tensile Strength: Typically around 350-600 MPa.

- Yield Strength: Approximately 100-250 MPa.

- Elongation: Generally around 15-30%, indicating good ductility.

- Hardness: Moderate hardness, with a typical Brinell hardness number (HB) of around 80-150.

- Machinability:

- Good machinability due to the presence of lead, making it suitable for machining and forming operations.

- Often used in the production of intricate parts and decorative items.

- Aesthetic Appearance:

- Attractive silvery appearance due to nickel content, making it popular for decorative applications.

- Good polishability, suitable for high-end finishes.

- Thermal and Electrical Conductivity:

- Good thermal conductivity, suitable for heat exchange applications.

- Moderate electrical conductivity, sufficient for many industrial uses but lower than pure copper.

Applications:

Decorative Items: Extensively used in the production of jewelry, musical instruments, and art objects due to its attractive appearance and tarnish resistance.

Architectural Applications: Commonly used in architectural elements such as railings, trim, and fittings where both strength and aesthetics are important.

Electrical Components: Employed in electrical connectors and terminals due to its good conductivity and corrosion resistance.

Industrial Equipment: Suitable for various industrial equipment parts, including gears, valves, and connectors, where good formability and machinability are required.