High Tensile Brass

- Home

- >

- Leaded Brasses

- >

- High Tensile Brass

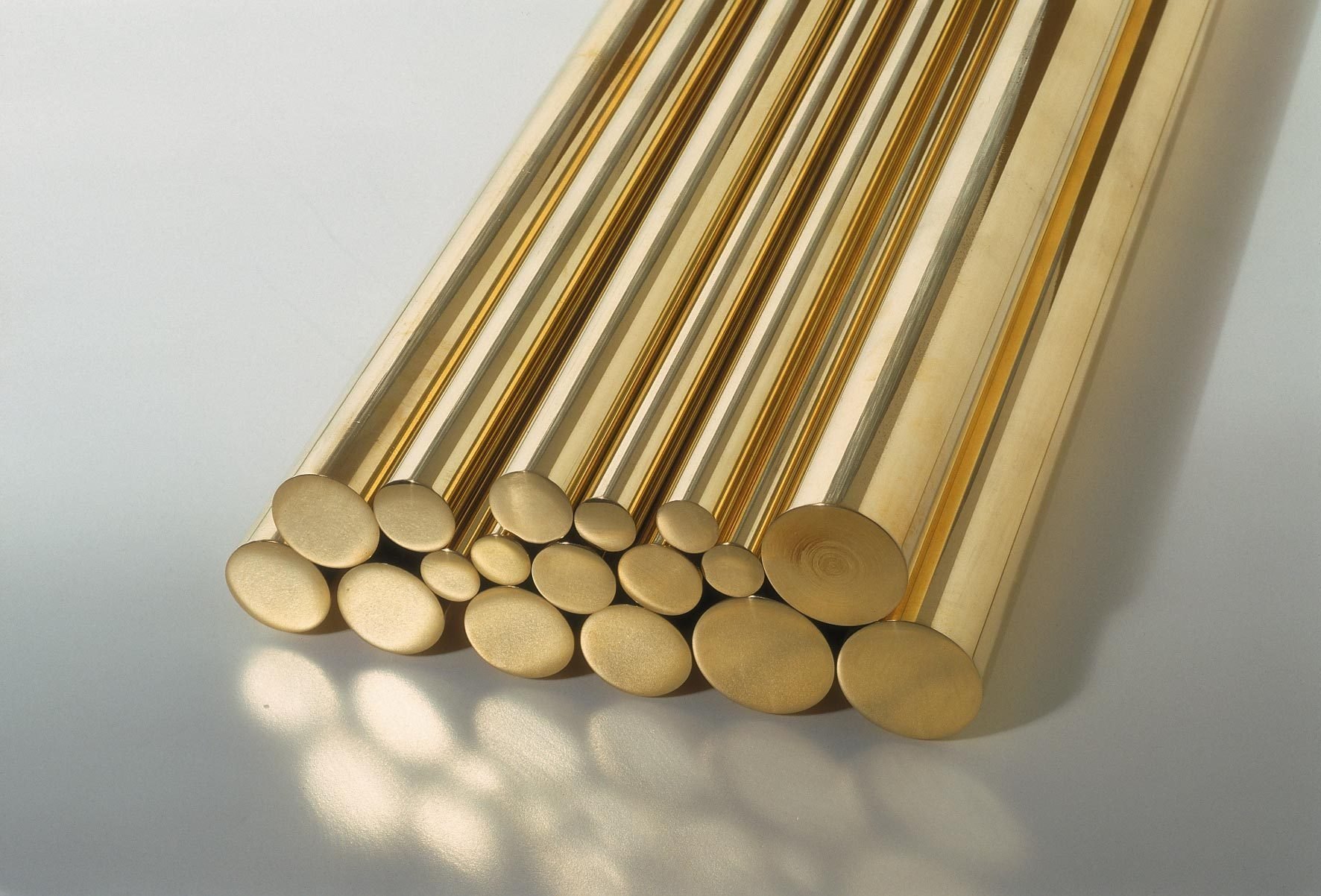

High Tensile Brass

High Tensile Brass, also known as Manganese Bronze or Leaded Manganese Bronze, is a type of brass alloy designed for applications requiring higher strength and toughness. The addition of lead improves machinability, while the presence of manganese and other elements enhances the mechanical properties and corrosion resistance.

Composition:

- Copper (Cu): Approximately 55-59%

- Zinc (Zn): Approximately 36-40%

- Lead (Pb): Approximately 0.8-2%

- Iron (Fe): Approximately 0.8-2.5%

- Manganese (Mn): Approximately 0.5-2%

- Aluminum (Al): May include small amounts to enhance specific properties

Grades

IS 320 HT1 or HT2:

Indian Standards specifying the composition and mechanical properties for high tensile brasses.

BS 2874 CZ114 or CZ115:

British Standards specifying the requirements for high tensile brass alloys.

JIS 3250H C6782 or C6783:

Japanese Industrial Standards specifying the requirements for high tensile brass alloys.

BS1001-Type I & II:

British Standards specifying the composition and mechanical properties for different types of high tensile brasses.

IS 8737 - II:

Indian Standards specifying the composition and properties for high tensile brasses.

Properties:

- Corrosion Resistance:

- Good general corrosion resistance, suitable for marine and industrial environments.

- Better resistance to seawater corrosion compared to standard brasses.

- Mechanical Properties:

- Tensile Strength: Typically around 550-750 MPa.

- Yield Strength: Approximately 200-300 MPa.

- Elongation: Generally around 10-25%, indicating good ductility.

- Hardness: Higher hardness compared to standard brasses, with a typical Brinell hardness number (HB) of around 100-150.

- Machinability:

- Good machinability due to the presence of lead, making it suitable for machining and turning operations.

- Often used in automatic screw machines and other machining equipment.

- Forgeability:

- Good forgeability, allowing for the production of complex shapes and high-strength components.

- Suitable for hot forging processes.

- Thermal and Electrical Conductivity:

- Good thermal conductivity, suitable for heat exchange applications.

- Moderate electrical conductivity, sufficient for many industrial uses but lower than pure copper.

Applications:

Marine Hardware: Extensively used in the production of marine hardware, such as propellers, shafts, and fittings, due to its strength and corrosion resistance.

Heavy Duty Bearings and Bushings: Used in heavy-duty bearings and bushings where high strength and good wear resistance are required.

Industrial Equipment: Suitable for various industrial equipment parts, including gears, valves, and connectors, where high tensile strength is needed.

Forged Components: Ideal for components that require forging, such as high-strength fittings, fasteners, and mechanical parts.