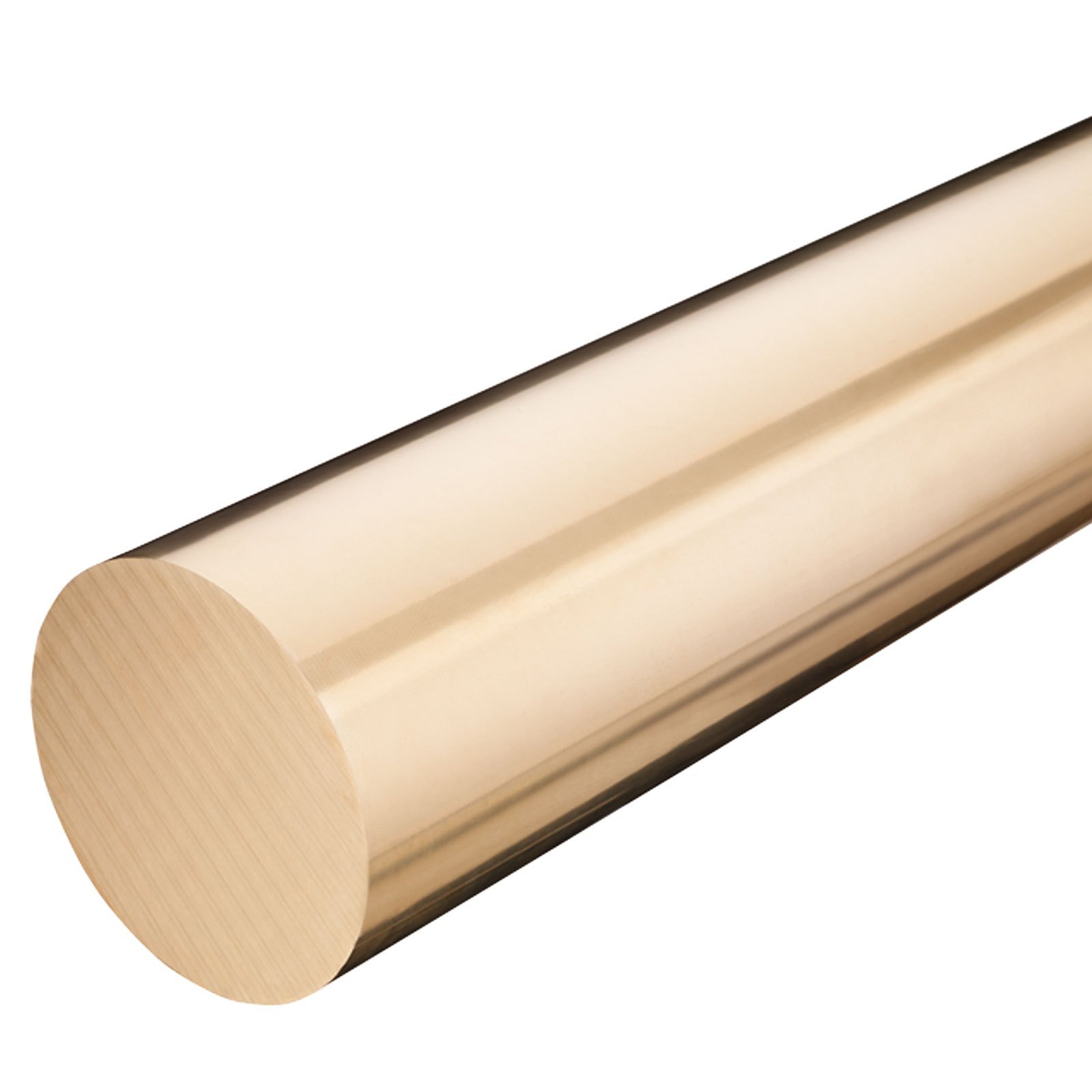

Nickel Alu. Bronze

- Home

- >

- Bronze

- >

- Nickel Alu. Bronze

Nickel Alu. Bronze

Nickel Aluminum Bronze (NAB) is a high-strength copper-based alloy with aluminum, nickel, and iron as major alloying elements. This alloy is known for its excellent corrosion resistance, high strength, and good wear resistance, making it suitable for demanding applications, particularly in marine environments.

Composition:

- Copper (Cu): Typically 75-85%

- Aluminum (Al): 5-12%

- Nickel (Ni): 4-6%

- Iron (Fe): 1-5%

- Other elements: Small amounts of manganese (Mn), silicon (Si), and tin (Sn).

Grades

IS 10569: 1983 - Grade I:

Known for its high strength and toughness, used in heavy-duty applications.

IS 10569: 1983 - Grade II:

Excellent wear resistance and good machinability, suitable for bearings and bushings.

IS 10569: 1983 - Grade III:

Good corrosion resistance and mechanical properties, used in marine and industrial applications.

Properties:

- Corrosion Resistance:

- Outstanding resistance to corrosion in marine and industrial environments.

- Excellent resistance to stress corrosion cracking and cavitation.

- Mechanical Properties:

- Tensile Strength: Typically around 600-800 MPa.

- Yield Strength: Approximately 300-500 MPa.

- Elongation: Generally around 10-20%, indicating good ductility.

- Hardness: High hardness, with a typical Brinell hardness number (HB) of around 150-250.

- Wear Resistance:

- Excellent wear resistance, suitable for applications involving high loads and friction.

- Good anti-galling properties, ideal for bearings and bushings.

- Machinability:

- Good machinability, allowing for the manufacturing and machining of complex components.

- Can be cast, forged, and worked to various shapes.

- Thermal and Electrical Conductivity:

- Good thermal conductivity, suitable for heat exchange applications.

- Moderate electrical conductivity, sufficient for many industrial uses but lower than pure copper.

Applications:

Marine Hardware: Widely used in marine hardware such as propellers, pumps, and valves due to its excellent corrosion resistance and high strength.

Bearings and Bushings: Extensively used in the production of bearings and bushings due to its high wear resistance and low friction properties.

Aerospace and Defense: Employed in the aerospace and defense industries for components requiring high strength, toughness, and corrosion resistance.

Industrial Equipment: Used in various industrial equipment parts, including gears, connectors, and fasteners.

Oil and Gas Industry: Suitable for components in the oil and gas industry, such as valves and fittings, due to its resistance to corrosive environments.